This could change everything

Or: 'How to enjoy printmaking again'

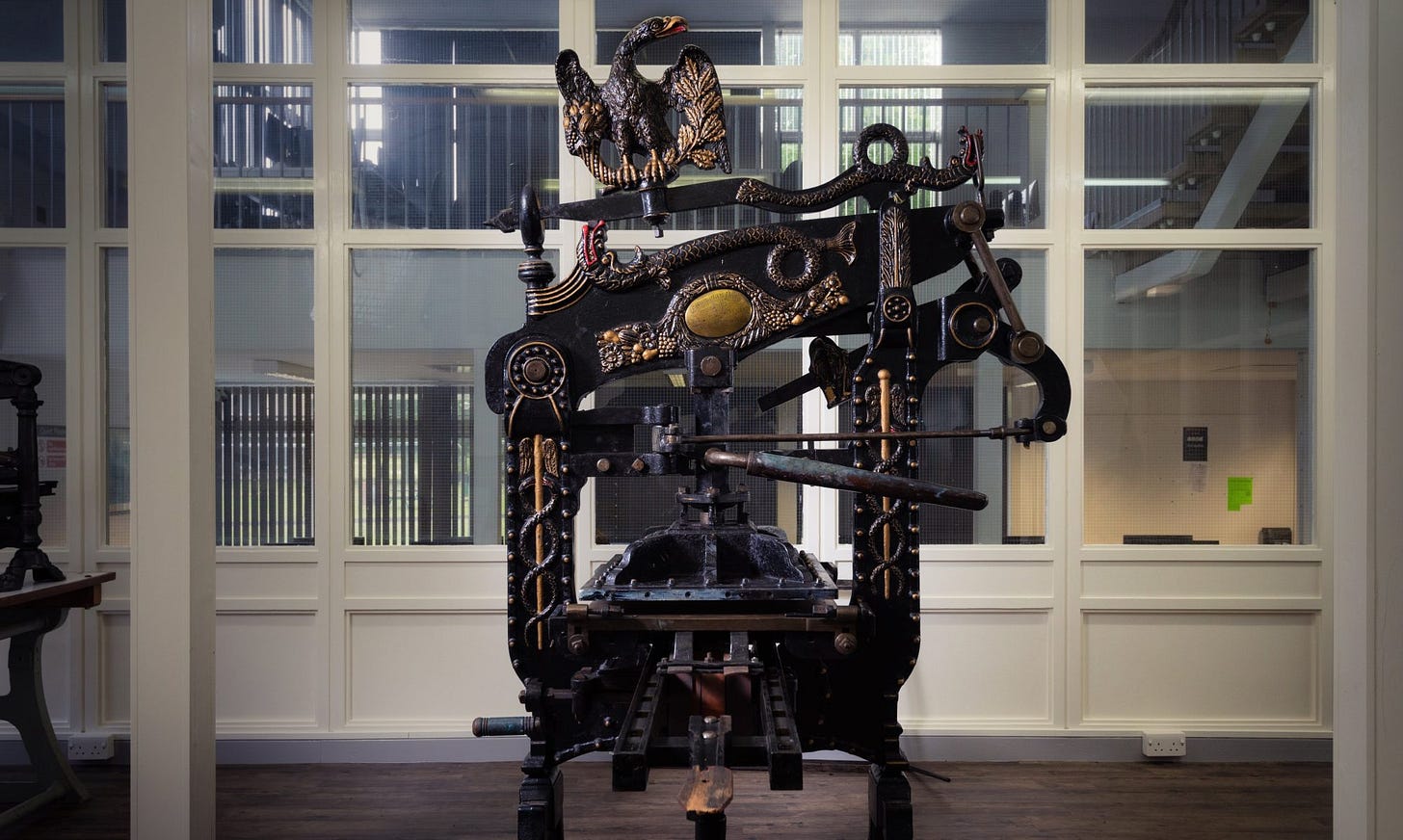

Printmakers working in relief as opposed to intaglio1 have a number of presses to choose from, but all have drawbacks. They can use a table-top lever press, which can be uncomfortable to use for large editions and is also limited to quite small prints. They can use an antique book press, which looks authentic and does the job, but is again very limited in print size. They can hand-burnish with a baren, a SLÁMA press or a wooden spoon, which all require varying degrees of elbow grease and can be unsatisfactory on heavier weights of paper. The dream is an Albion or Columbian press - a full size press which exerts vertical pressure from above - but this requires both deep pockets and a lot of studio space (and a strong floor).

Many relief printmakers end up using a roller press especially if, like me, that is what they already have in their studio. The trouble is that roller presses are primarily designed for intaglio methods in which thin paper and plates are passed through under great pressure. Lino and wood are much thicker and if there is enough contact between the bed and roller to move the bed along, then when the lino or wood is reached the roller is going to bash into it, and either stop dead or risk damaging the press if the obstruction is forced though. The traditional way to combat this is to create runners along the edges of the press bed with cut strips of lino, so that the press roller rests on these rather than directly on the press bed, but these are only as deep as the lino, and don’t allow for the paper or any registration jig, so there is still going to be a jolt. Certainly I have never been able to get satisfactory results this way; if I had enough pressure to transfer the ink, then it would be too much pressure for the print to pass through smoothly, resulting in drag and (the curse of printmaking) messed-up registration.

Then along came Ironbridge Fine Arts and their purpose-made runners.

My first sight of these was a post on Instagram and from that I investigated further on their website. I was sold. TAKE MY MONEY. I chose a pair of 8mm deep runners which allows for 3.2mm deep lino plus a registration jig made from 3mm deep greyboard, plus the printing paper (in my case 250gsm Somerset Satin) and then a bit of room to spare, as recommended by Ironbridge. The idea is you make up the difference with sheets of packing paper to get pinpoint precision in the amount of pressure applied - neither too much (dragging the print) nor too little (poor printing) but just right (as approved by Goldilocks). The packing paper needs to be robust and smooth; I had Fabriano Accademia drawing paper to hand in the studio and with experimentation found the sweet spot was 5 sheets on top of my printing paper and lino.

Here is some lino set up in a registration jig between the runners. You might spot I am using two sets of registration tabs, rather than just at one end as I do when hand burnishing. This further reduces the risk of the paper moving slightly through drag because just a millimetre of slip is enough to ruin the registration.

And here’s a video of the runners in action on my Hawthorn Printmaker press. I have left the sound on so you can enjoy the atmosphere of the press clanking and the registration tabs clicking, but it does mean you also get my cat yowling in the background. Sorry about that, but think yourself lucky that you don’t get it all day like I do. Don’t expect too much of the reveal at the end; this print is still at the pretty awful looking ‘random patches of colour’ stage. I have hopes this will start resolving in the next couple of layers. (The white paint on my elbow, by the way, is from painting a door frame that morning. Printmaking is messy but not that bad).

So the result is near effortless printing and (so far) good registration. This, together with my new inks, is going to make printmaking a pleasure again and I might even be able to face making larger prints and in bigger editions, which I have shied away from when printing by hand burnishing.

The next time I write I should have finished this print, and I’ll have a clearer idea of the success of this method. If you have any questions, or want to say anything else, do please chip in using the button below. When people comment here rather than emailing then it becomes a conversation that everyone can join, which can be really helpful, and just nicer really. (Emails are of course welcome if there is something you want to say privately).

Blowing my own trumpet

When I last wrote I talked about handing in some pieces to an exhibition in the National Park Centre in the North York Moors. I wasn’t able to go to the Preview but saw some photos online and began to get anxious that one of my pieces hadn’t been hung. I summoned up the courage to email the gallery and ask about it. Perhaps it had been lost or damaged, or was it just too awful to be displayed? The answer came back that the print, Morning Bluebells, didn’t make it through the Preview evening because it had immediately sold, the first sale of the exhibition. So that’s alright then…

Morning Bluebells is a small edition of 8 prints of which 6 have now sold. I want to keep one of the remaining two for the York Printmakers Print Fair in September so there is now just one left in my online shop, should that be something you want to know. The image below is a direct link.

Thanks for reading and see you again soon

Jane

In a relief print (eg linoprint or woodblock) the area that is NOT to be printed is carved away and the ink is applied to the raised areas remaining. In intaglio (eg etching) the image to be printed is carved into the block and the ink is pushed down into those lines.